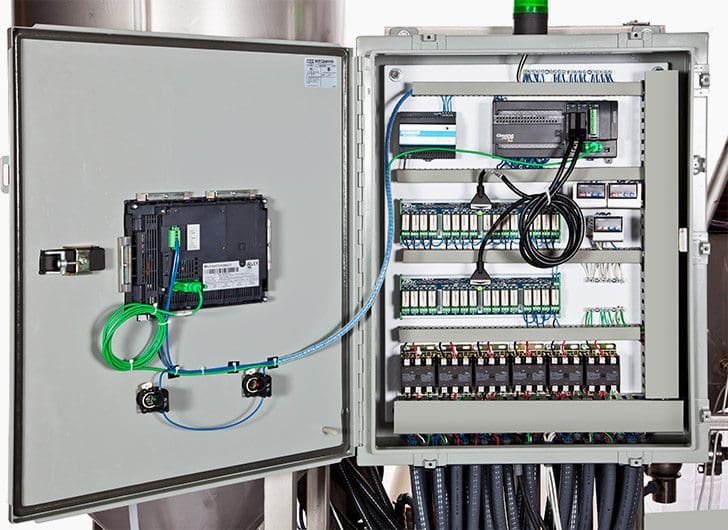

If the liquid level reaches the HIGH LEVEL float, the alarm light and buzzer on the control panel will be activated. The only reason the water level should ever reach the PUMP 2 ON (LAG ON) switch is because PUMP 1 has failed or cannot keep up with the incoming flow. If you are using a 4 float setup, and the water level reaches the PUMP 2 ON (LAG ON) float switch, then the alternate pump not set to normally come on will be activated. At this time the alternating relay will switch to PUMP 2 and it will follow this same cycle and the alternating relay will switch back to PUMP 1 and so on. To achieve this goal, good choices of a hardware platform comprising a. This means that once the liquid level reachs the PUMP ON float that PUMP 1 will run until the liquid level reachs the PUMP OFF float. In this work, the design of a robust lift group control system based on programmable logic controllers (PLC) is introduced. The control panel has an alternating relay that switches between PUMP 1 and PUMP 2 after every cycle during automatic operation. A 4 float setup would have a PUMP OFF, PUMP 1 ON (LEAD ON), PUMP 2 ON (LAG ON), and HIGH LEVEL floats. Design & Development of a Lift Station Control Panel for City click to enlarge STA-CON LLC is a team of experienced engineers who work closely with our customers to design and develop the perfect control panel for their individual application.

The standard 3 float setup has PUMP OFF, PUMP ON, and HIGH LEVEL floats. OPERATION OF A DUPLEX CONTROL PANELĪ standard duplex control panel can operate with 3 or 4 float switches. This type of set up ensures that you will always have at least one pump in working order.

If one of the pumps fails, the panel will give the high water alarm, and automatically kick on the other pump. Our Duplex panels will alternate cycles between the two pumps, making sure both are in working order throughout the lives of the pumps. The most common application for a duplex control panel is a system that needs a backup pump in place in case the original pump fails. Our services for repairing and retrofitting control panels is a great advantage to lift station owners and operators.Duplex Control Panels are designed to control a pump stations with two submersible sewage or effluent pumps. Romtec Utilities offers some of the most complete expertise available when it comes to lift station control panels. We make sure your staff has the necessary knowledge and resources to keep your pump or lift station controller working great. Our training services are a key aspect of providing long-term control panel solutions. Romtec Utilities completes repair and retrofit services by training your staff and personnel in the operation and maintenance of the control panel.

Lift control panel design code#

Elevator Control Panelboards Elevator control panelboards integrate electrical protection and controls for elevators and meet stringent code requirements in a single, cost-effective package.

Lift control panel design how to#

The same goes for understanding SCADA systems and how to properly integrate existing controls. 15 A and 20 A bolt-on breakers in panel-boards meet Article 210.12 of the NECT. Understanding the complete breadth of lift station components is very important to make sure a control panel retrofit will function correctly with any new pumps, level devices, flow meters, or other system components that have been added. In these situations, it is imperative to use a company with substantial lift station experience.

Lift control panel design update#

Retrofits may also be a good option for lift stations that have been recently updated or to update the telemetry of a control panel, such as integrating with a new or existing SCADA system.

Romtec Utilities makes sure this is the case and that a control panel retrofit is more than a quick fix. In these scenarios, replacing failing components can be difficult or impossible, making it preferable to retrofit the panel to utilize newer technologies that are readily available from reliable manufacturers. A common scenario is when an aging control panel utilizes components that are no longer available or are difficult to find in the market. In these circumstances, it is sometimes possible to retrofit an existing panel without needing to replace it. Sometimes control panels need to be serviced beyond a simple repair. Romtec Utilities offers expertise in the design, manufacture, and operation of pump and lift station control panels, and our expertise can also be used to conduct control panel repairs for a long-term solution to a failing or faulty control panel. These types of problems can occur as a result of past redesigns, the age of the controller or its enclosure, or components operating past their life expectancy.

These repairs can range from simply replacing failing components to finding and repairing a source of recurring problems. Control panels can get worn down over time and may require repairs.

0 kommentar(er)

0 kommentar(er)